As manufacturers come up with new industrial applications, they increasingly rely on linear motion systems because of their reliability, high speed, accurate positioning, long life and low maintenance.

Like many robotic material handling manufacturers we work with, Miller Weldmaster Corporation needed linear actuators that could withstand the elements of thermoplastic and industrial fabric production—the mess, the stress and the harsh environments. Their clients needed machines for a wide variety of uses: heat-sealing seams of billboard panels, inflatable boats and truck tarpaulins. That meant they needed to accommodate a variety of lengths, speeds and payloads.

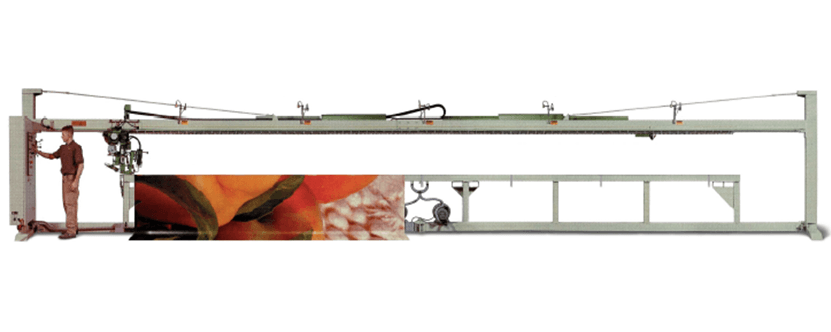

Here's a look at the company's Model 112 Cross Seamer, which they designed to provide the quickest, most attractive seam for the flexible sign industry.

As you can see, it's pretty long. In this case, 20 meters end to end. DualVee components gave this machine a rigid, smooth and modular linear guidance system. They used T3 drilled track bolted to a butt-jointed steel beam that makes it easier to customize based on their customers' needs. The W3 DualVee wheels are mounted to a custom carriage plate, which carries the welding head.

We live for long length challenges!

For more application stories, visit our archives here.

Like many robotic material handling manufacturers we work with, Miller Weldmaster Corporation needed linear actuators that could withstand the elements of thermoplastic and industrial fabric production—the mess, the stress and the harsh environments. Their clients needed machines for a wide variety of uses: heat-sealing seams of billboard panels, inflatable boats and truck tarpaulins. That meant they needed to accommodate a variety of lengths, speeds and payloads.

Here's a look at the company's Model 112 Cross Seamer, which they designed to provide the quickest, most attractive seam for the flexible sign industry.

As you can see, it's pretty long. In this case, 20 meters end to end. DualVee components gave this machine a rigid, smooth and modular linear guidance system. They used T3 drilled track bolted to a butt-jointed steel beam that makes it easier to customize based on their customers' needs. The W3 DualVee wheels are mounted to a custom carriage plate, which carries the welding head.

We live for long length challenges!

For more application stories, visit our archives here.